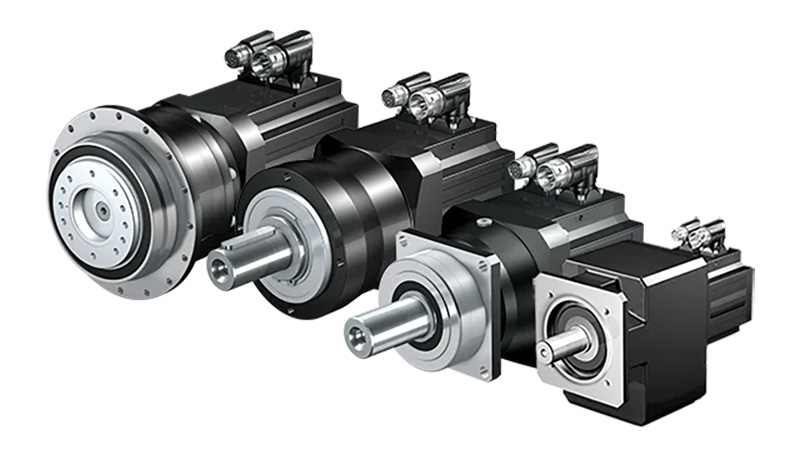

Unlock Precision & Performance with STOBER Inline Synchronous Servo Geared Motors

In today’s automation-driven world, motion control systems demand more than raw power—they require precision, efficiency, flexibility, and absolute reliability. STOBER’s Inline Synchronous Servo Geared Motors deliver all of this and more, offering one of the industry’s most versatile and high-performance solutions for machine builders, OEMs, and system integrators.

Designed for demanding applications and engineered with German precision, STOBER inline geared motors combine servo technology, tight manufacturing tolerances, and robust mechanical design to deliver a seamless blend of speed, torque, and efficiency across every motion profile.

Why Engineers Choose STOBER Inline Servo Geared Motors

1. Seamless Integration for High-Performance Automation

STOBER synchronous servo geared motors are available as fully integrated motor + gearbox units, minimizing mechanical backlash and delivering exceptionally smooth motion—even in high-speed and high-precision environments.

The result?

Cleaner installs, fewer components, and superior long-term performance.

2. Brushless, Permanent Magnet, Electronically Commutated

Every STOBER servo motor is built for longevity and accuracy. Their synchronous servo motors feature:

Brushless operation for long life and low maintenance

Permanent magnet design for high torque density

Electronically commutated architecture for precise, dynamic motion

These motors remain efficient across various load conditions, ensuring consistent performance even in highly dynamic applications.

3. A Wide Range of Power Profiles

Whether you’re designing for compact packaging equipment, robotics, conveyors, or specialized motion platforms, STOBER offers multiple motor sizes and power options, including:

High-speed profiles

High-torque configurations

Low-inertia designs

Efficiency-optimized options

This flexibility ensures the right fit for virtually any engineered system.

4. Gear Technology That Sets the Standard

STOBER’s inline gear units are manufactured to extremely tight tolerances, delivering:

Low backlash

High torsional stiffness

Durable gear geometry

Quiet, efficient operation

Because these gear units are integrated directly with the servo motor, engineers eliminate the alignment, couplings, and potential failure points commonly found in traditional motor-gearbox pairings.

5. Industry-Proven Reliability

Every STOBER product is backed by decades of German engineering excellence and testing. Inline servo geared motors are widely used in:

Factory automation

Robotics

Packaging machinery

Material handling

Food & beverage equipment

High-cycle production systems

They’re simply built to perform—day after day, cycle after cycle.

Built for Demanding Motion Control Applications

STOBER inline servo geared motors shine in systems requiring:

Rapid acceleration and deceleration

Precise positioning

High repeatability

Continuous duty cycles

Zero maintenance downtime

From delicate automated assembly to heavy-duty industrial motion, STOBER motors deliver consistent, dependable performance that engineers trust.

Explore the Full Line of STOBER Inline Servo Geared Motors

If you’re looking for a geared motor solution that combines precision, power, and long-term reliability, STOBER’s inline synchronous servo geared motors offer a complete performance package.

🔗 Learn more and explore the full range:

https://www.stober.com/servo-products/inline-geared-motors/